![]() was awarded the Environmental & Social Impact Assessment (ESIA) Consultancy Services for the Turkmenistan- Afghanistan-Pakistan-India (TAPI) Gas Pipeline as part of the early feasibility and engineering phase. We were supported by by JACOBS / CH2M’s specialized experts during execution.

was awarded the Environmental & Social Impact Assessment (ESIA) Consultancy Services for the Turkmenistan- Afghanistan-Pakistan-India (TAPI) Gas Pipeline as part of the early feasibility and engineering phase. We were supported by by JACOBS / CH2M’s specialized experts during execution.

Our services include Identification of specific mitigation measures and actions necessary to comply with National Applicable Law (NAL) and International Environmental and Social Standards (IESS) and other applicable requirements, to reduce risks and enhance benefits.

![]() and Houston based TPL are long-term partners. TPL is a world class company consistently providing high quality services to the Energy Industry. The joint venture has been awarded several contracts by major IOC’s to deliver facility consultancy services including procedure-based competency assurance, at all levels of client’s organization.

and Houston based TPL are long-term partners. TPL is a world class company consistently providing high quality services to the Energy Industry. The joint venture has been awarded several contracts by major IOC’s to deliver facility consultancy services including procedure-based competency assurance, at all levels of client’s organization.

Under our local JV subsidiary in Iraq, we were awarded major contracts to provide training and development services:

![]() for West Qurna-1 Project, we were awarded a 3-year contract to provide a Learning and Development Program, including Training Facility Management, Technical Instruction Services, Competency Assurance, Trainee Assessment & Enhancement

for West Qurna-1 Project, we were awarded a 3-year contract to provide a Learning and Development Program, including Training Facility Management, Technical Instruction Services, Competency Assurance, Trainee Assessment & Enhancement

![]() is a long-term partner of Operation Technology, Inc. (OTI), a full spectrum analytical engineering firm and the developer of ETAP, the most comprehensive enterprise solution for design, simulation, operation, control, optimization, and automation of generation, transmission, distribution, and industrial Power Systems.

is a long-term partner of Operation Technology, Inc. (OTI), a full spectrum analytical engineering firm and the developer of ETAP, the most comprehensive enterprise solution for design, simulation, operation, control, optimization, and automation of generation, transmission, distribution, and industrial Power Systems.

OTI’s corporate office is located in Irvine, California which encompasses the entire research and development team, engineering division, and supporting staff.

OTI extends its global reach with sales and support offices in more than 80 countries and has more than 50,000 licenses in over 100 countries.

ADNOC is one of our key clients in the middle east and we are continuously providing our solutions to all its subsidiaries (ADNOC Gas Processing, ADNOC Refining, ADNOC Offshore).

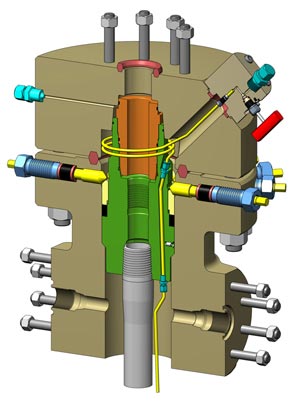

Q-Seal Wellhead Hanger Seal is an engineered solution to address the problem of tubing and casing hanger leaks, without requiring well intervention, and with no risk.

Q-Seal Wellhead Hanger Sealant consists of a matrix of sealing micro-particles distributed within an inert viscous matrix. The product is injected into the hanger test cavity where it migrates to, and seals, the leak site.

Q-Seal technology is the product of extensive development and testing. Each well application is individually investigated to ensure that the solution is appropriate to the leak mechanism and delivered in the most effective manner.

Among our key clients in the middle east: Total and Dubai Petroleum.